October 2022 – August 2023

In 2022, a major Turkish commercial vehicle manufacturer—well established in diesel-powered city buses—made a strategic decision to enter the electric vehicle market. Their product roadmap included two new platforms: an 8-meter and a 12-meter electric city bus, designed for the European market.

The company needed a qualified battery technology partner capable of delivering hv battery solutions, certification support, system integration guidance, and application engineering. To avoid the cost and delay of a full ground-up development program, we proposed a mature and scalable 280 kWh lfp battery system, perfectly suited for the 8-meter platform while offering room to expand for larger models.

This approach enabled rapid entry to market while maintaining European compliance and long-term reliability—critical performance criteria for urban transportation applications.

Although the manufacturer had years of combustion bus development experience, they faced several hurdles transitioning into electric drivetrains:

The customer required a 700V hv custom battery packs architecture, significantly higher than typical 300V–540V EV platforms. This demanded redesign of:

The battery system needed to pass two critical certifications:

For a company new to EV systems, these requirements represented an engineering and documentation challenge. To ensure success, we provided direct support throughout the certification process.

Ships account for nearly 3% of global greenhouse gas emissions, and the maritime industry is under growing pressure to decarbonize. From harbor tugboats to inland ferries, Brogen believes electrification is not only possible—it’s necessary.

We are committed to helping shipbuilders, fleet operators, and governments transition to electric marine platforms. With advanced Battery, BMS, and thermal management solutions tailored for harsh marine conditions, we offer global support for low-carbon transformation.

Whether you're designing a commercial vessel, offshore workboat, or pleasure craft, we’re ready to power your next-generation marine project—safely, efficiently, and sustainably.

We supplied a complete high voltage batteries system, including mechanical structure, electrical layout, BMS, and validation support. The delivered system contained:

Before contract finalization, we conducted detailed engineering analyses:

We also provided guidance on component certification, including:

This ensured compliance, reduced cost, and accelerated approval timelines.

During system design, we executed:

Since the buses adopted a European charging standard, we:

This ensured the buses would charge reliably upon delivery without additional field engineering.

Once onsite, the customer performed installation and testing. We provided:

When the customer's testing computers exhibited compatibility issues with our configuration software, our engineering team delivered several iterative software builds and successfully reflashed BMS units remotely.

Today, the buses are undergoing final road condition trials with stable operation and verified power performance.

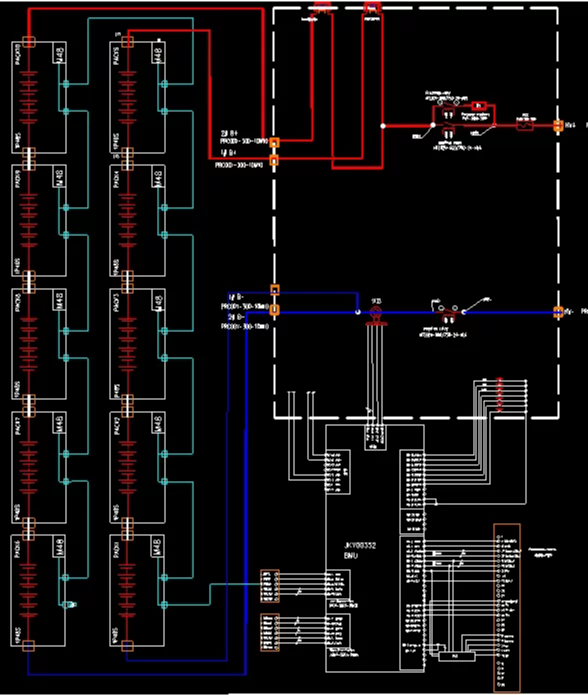

Recording of the actual project process

This project delivered:

The partnership proved that the right high voltage batteries and custom battery packs can significantly shorten time-to-market for manufacturers transitioning to electrified platforms.

This case demonstrates how a traditional commercial vehicle OEM successfully transitioned to electric buses using a mature and cost-optimized lfp battery system, complete with engineering support, certification guidance, and customized hv battery integration.

If you are:

👉 Contact us for technical evaluation, quotation, or product consultation.

We help OEMs and system integrators reduce development risk, accelerate launch schedules, and deploy safe, compliant, and competitive electric mobility solution

Ships account for nearly 3% of global greenhouse gas emissions, and the maritime industry is under growing pressure to decarbonize. From harbor tugboats to inland ferries, Brogen believes electrification is not only possible—it’s necessary.

We are committed to helping shipbuilders, fleet operators, and governments transition to electric marine platforms. With advanced Battery, BMS, and thermal management solutions tailored for harsh marine conditions, we offer global support for low-carbon transformation.

Whether you're designing a commercial vessel, offshore workboat, or pleasure craft, we’re ready to power your next-generation marine project—safely, efficiently, and sustainably.

Contact Brogen to find the electric vehicle power solutions that best fits your business.