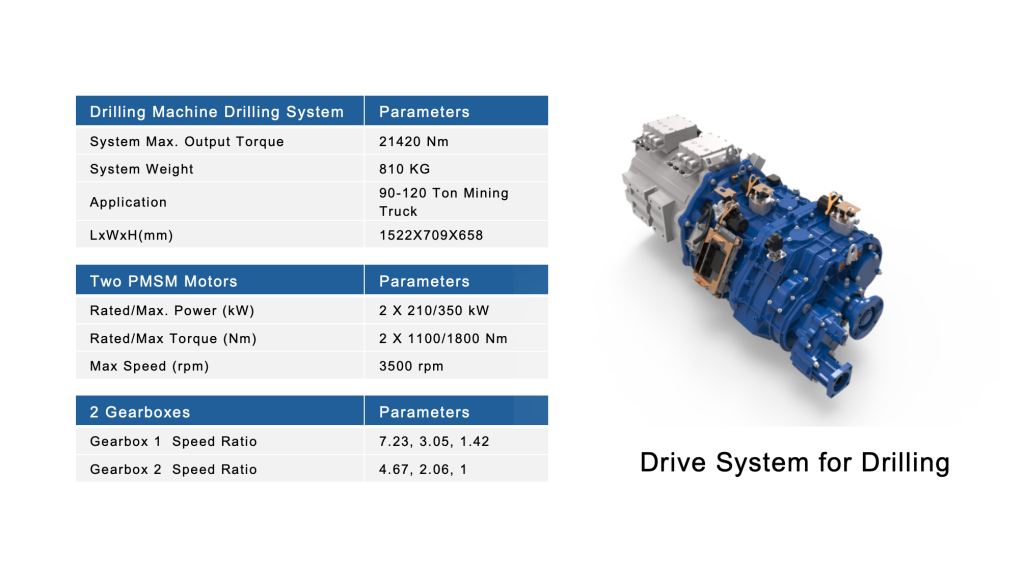

In January 2025, a renowned drilling rig equipment company based in Australia approached Brogen with a bold vision: to electrify its entire fleet of heavy trucks and integrated drilling equipment. Facing urgent timelines and component delivery constraints, the client needed a partner capable of delivering a full-stack battery system solution — not just standalone packs, but a tailored integration of BMS, BTMS, HV box, and electric drive modules.

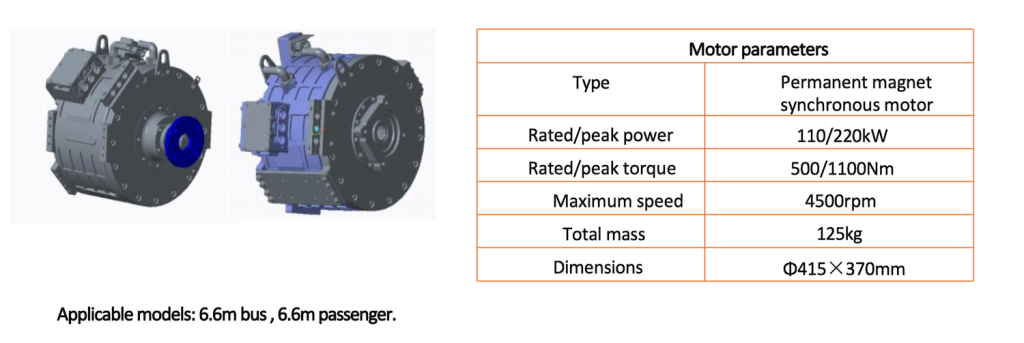

Over the course of the collaboration, Brogen has already delivered a fully operational electric drive solution for the first heavy-duty crew carrier truck and motorized components for the rig system. Now we are helping in the battery solution of drilling rig. The project will eventually scale to more than 20 electric trucks by 2030.

The client sought a solution that could meet industrial-grade energy demands while avoiding the costs and delays of custom mold development.

Key challenges included:

The complete package delivered includes:

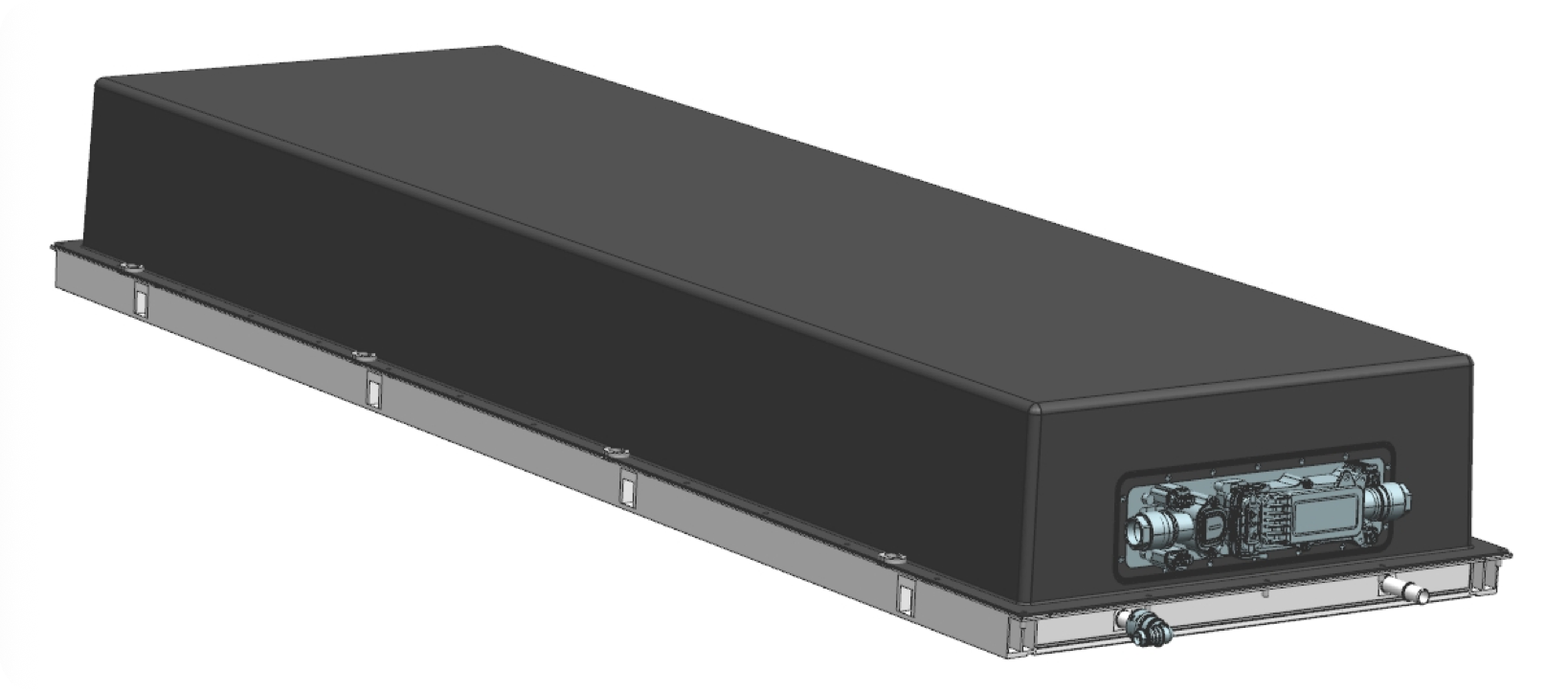

| 2C Fast Charging Pack for Heavy Truck |  |

| Model | B29 |

| Energy/kWh | 100.16 |

| Connection | 1P200S |

| Voltage/V | 640 |

| Capacity/Ah | 156.5 |

| Cell dimensions/mm | 580*120*17.9 |

| Pack dimensions/mm | 2173*700*275 |

| Energy density/Wh/kg | ≥150 |

| Vibration requirements | GB 31467.3 |

| Charging time (20~80% SOC) | <20min |

| Maximum continuous charging current (A) | 300 |

| Maximum peak current (A) | 470 |

| System cycle life | >4500 |

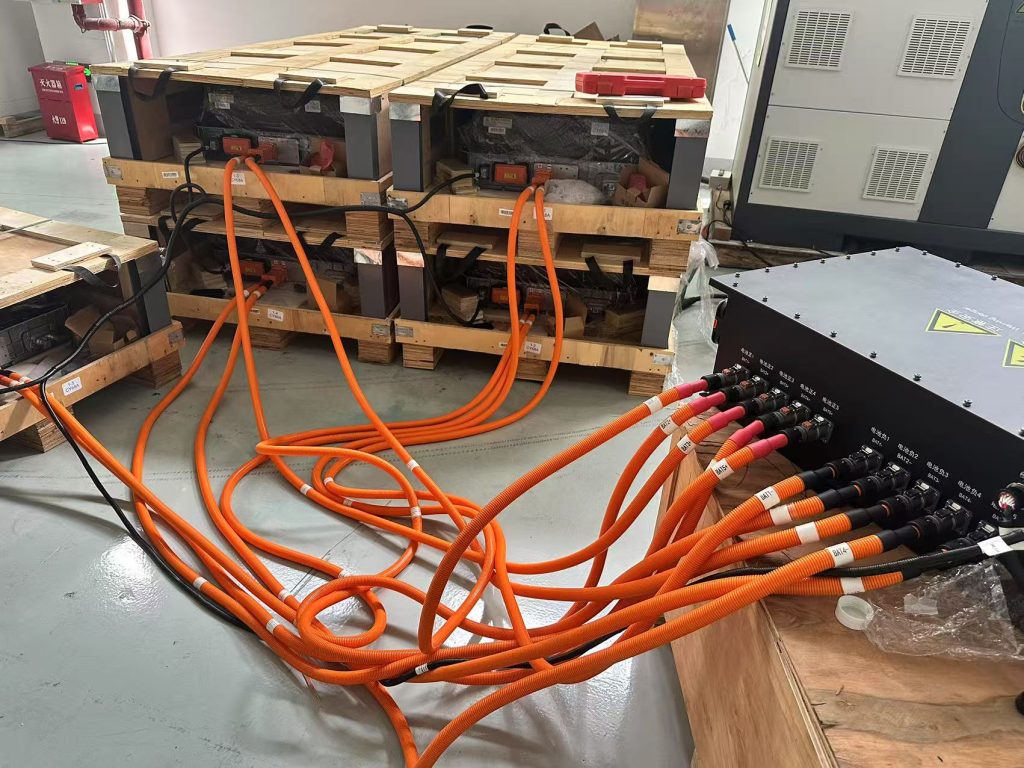

Thermal performance is critical in the rugged, high-variance environment of drilling operations, with ambient temperatures ranging from 5°C to 50°C. To manage heat from five parallel-connected battery packs, a high-performance BTMS is essential.

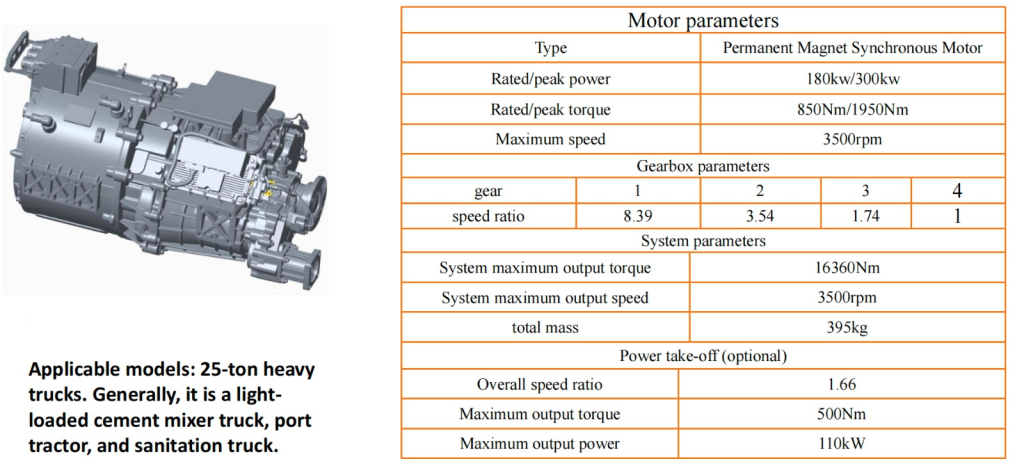

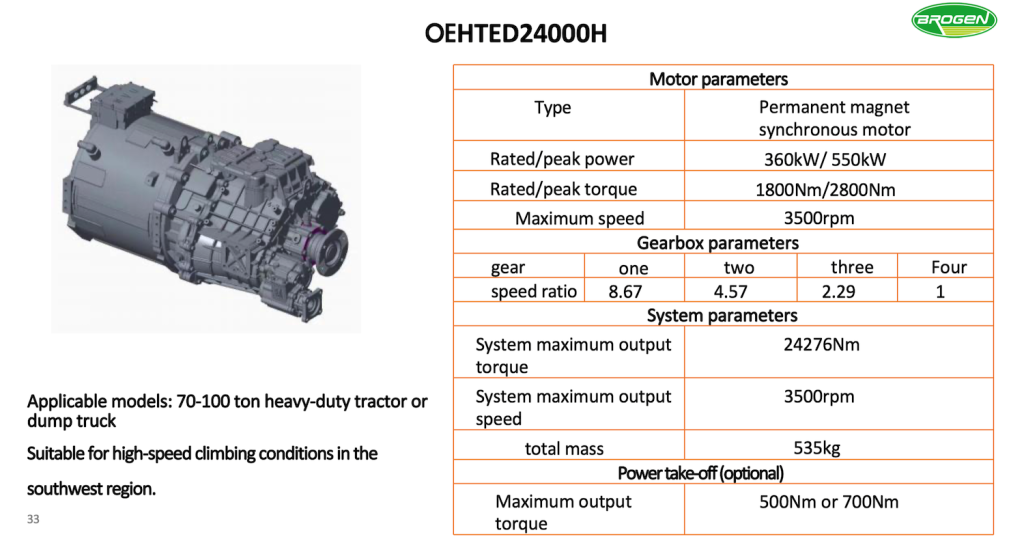

Brogen’s approach to electrification is holistic. In addition to battery systems, we deliver:

Drilling sites—especially in remote or high-impact zones—are under increasing pressure to reduce their carbon footprint and operational noise. Traditional diesel-powered drilling rigs and heavy trucks not only emit high levels of greenhouse gases but also incur rising fuel and maintenance costs.

At Brogen, we are committed to helping industrial clients in the drilling and exploration sectors transition to clean energy systems through reliable battery-powered platforms. Electrifying heavy-duty fleets isn't just a technological upgrade — it’s a statement of environmental responsibility.

By replacing combustion-driven rigs with battery-powered systems, operators can:

Whether you’re operating in Australian outback or Middle Eastern deserts, Brogen offers the engineering expertise and component reliability needed to bring your vision for zero-emission drilling operations to life.

Ready to transform your drilling rig & fleet with advanced battery solutions? Contact our experts to begin your electrification journey.

Contact Brogen to find the electric vehicle power solutions that best fits your business.